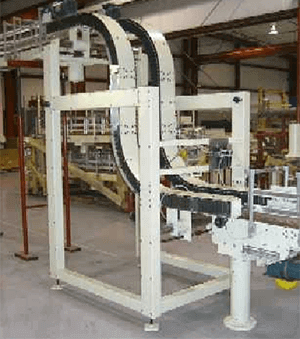

Gripper Conveyors for Elevating, Lowering and Orientation

The term "Gripper" is an industry wide term as this suggests that two parallel conveyor sections mounted side by side on a support structure that actually grips product and transports it, in an elevating or lowerating movement, while incorporating a buffer at the end of a conveyor or between different conveyors. Products are gripped gently but neoprene gripper bulb chains providing complete control of the product before delivering it onto another section of the conveyor.

The term "Gripper" is an industry wide term as this suggests that two parallel conveyor sections mounted side by side on a support structure that actually grips product and transports it, in an elevating or lowerating movement, while incorporating a buffer at the end of a conveyor or between different conveyors. Products are gripped gently but neoprene gripper bulb chains providing complete control of the product before delivering it onto another section of the conveyor.

Gripper elevators and lowerators come in various shapes including C Style, S Style and Upenders. The upender style gripper actually orients the product by 90º (S-Style) and 180º (C-Style) as it lifts the items from an infeed conveyor, carries the product to either a higher or lower elevation before the discharge.

Multi-Conveyor can also provide bypass table-style-top conveyor sections to allow product to flow through when elevation or reorientation is not required. A control panel with enclosed VFD is customizable with a simple toggle switch allowing the operator to “pass” the gripper or “transport” with ease. Grippers also typically come on casters for portability and maintenance.

(Images: The conveyor on the left is a typical S-Gripper whereas the image on the right shows a standard C-Gripper.)

Will a gripper help solve your production orientation solution?

Let's talk. 1-800-236-7960.

Or request more information here: